Purchase Tickets

Conserving the Madam C.J. Walker Collection

From artistic sketches to advertising layouts to architectural drawings to typewritten business documents, translucent and transparent “onionskin” papers are abundant in the IHS archives. But they pose a challenge for conservators, since traditional mending techniques are often not appropriate for these types of papers. Transparent papers are reactive to moisture, and applying a water-based adhesive can cause the paper to deform. It can also be difficult to find mending papers that are strong but also thin enough to blend in with the object. Most repairs are too visible on transparent documents, obscuring the writing or distracting from the visual impact of the piece. Luckily, cutting-edge nanotechnology has a solution for this conservation conundrum.

The IHS Conservation Lab hosted the “Applications for Nanocellulose Films in Conservation” workshop in June. The workshop was organized by the Foundation for Advancement in Conservation with support from the Mellon Foundation. Rémy Dreyfuss-Designe, a paper conservator working in France who has been researching nanocellulose papers and films since 2014, taught the intensive two-day workshop. Fourteen conservators from across the U.S. and Canada participated in lectures, discussions and hands-on experimentation.

Breaking down cellulose fibers to their very smallest nanoparticle size produces a highly purified product with advantageous optical qualities – the size and alignment of particles allow light to pass evenly through paper. Nanocellulose fibers can be purchased in gel form, diluted with water and cast into thin films. When the films dry, they can be applied to torn documents with a solvent-based adhesive. Workshop participants had a chance to make and use these nanofilms, as well as experiment with some alternative treatment techniques like mixing the nanocellulose gel with adhesives to produce composite films and applying those films directly to torn documents. This allows for repair of some tears without having to use any adhesive at all.

The results are promising, and IHS conservators have already put this knowledge to work in the Madam C.J. Walker collection. As the Library and Archives division digitizes the Madame C.J. Walker collection – made possible by a Digitizing Hidden Special Collections Grant from the Council on Library and Information Resources – they found an assembly of design drawings on tissue. These drawings presented an issue of paper transparency that needed to be maintained for the scanning process, while remaining true to the nature of the original materials.

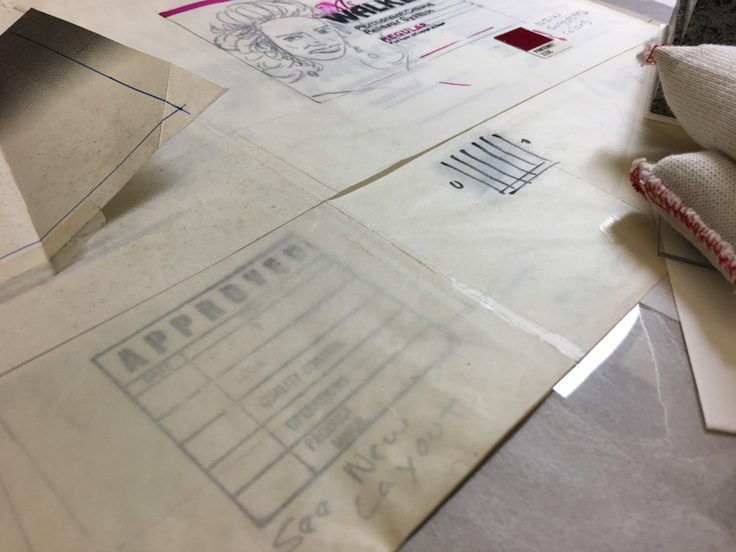

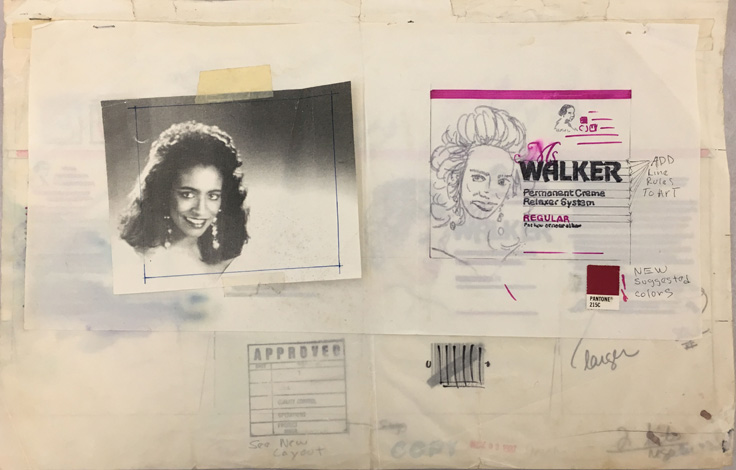

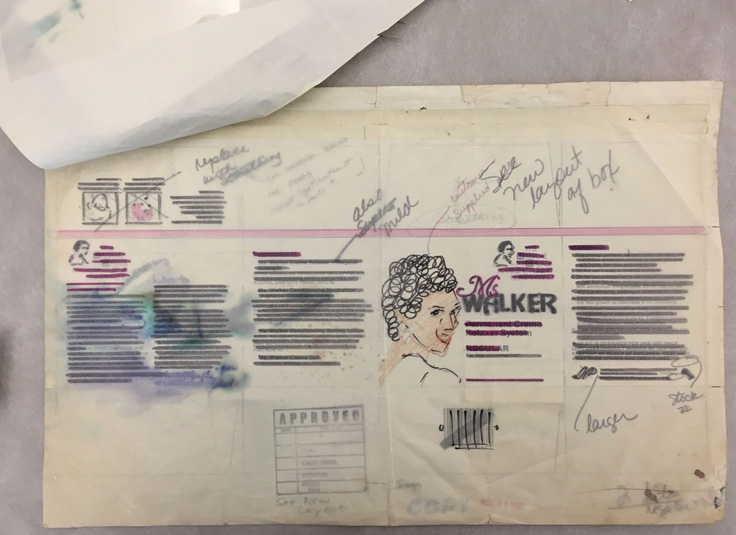

Proposed packaging design for Madam Walker Permanent Crème Relaxer System, 1987

Typical assemblies such as these reflect the artist’s design process as it moves from the beginning through the final phase. This work includes various weights and types of paper. The variety of media used include pencil, felt tip marker, ballpoint pen and stamped ink. Although stained from unknown sources, storage in a damp area is likely responsible for the damage to various inks that bled across the surface. Notations, creases, tape and staples are common to working drafts and could be of interest to researchers. Lab treatments should have minimal impact on changes to the original. Beyond staple removal, which allows the sheets to be viewed individually, repairing edge tears due to use required mending with consideration of page transparency.

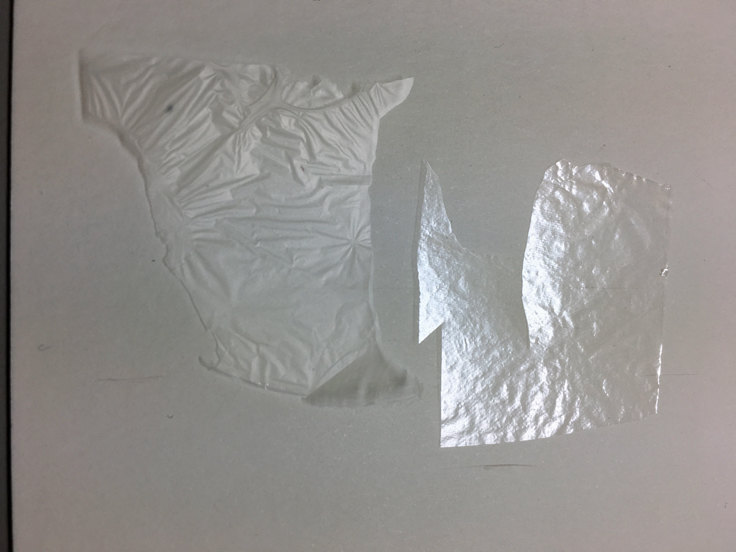

Transparent papers can be difficult to mend because the surface does not allow typical pastes to stick. Applying a lightweight tissue-mend would add thickness to the sheet and affect its transparency. This is where the knowledge from the nanocellulose workshop comes in. When nanocellulose in paste form is diluted with water, cast onto a surface and allowed to dry, it becomes a transparent sheet. The resulting film is 100% cellulose. It is thin yet strong and can be used in place of a tissue paper mend with a clear-drying acrylic adhesive.

When used on its own on a suction table, nanocellulose in liquid form can be brushed across the surface of a paper tear. The liquid bonds to the original with the help of the downward force of the suction without the use of an adhesive. The result in either instance is a transparent mend when viewed full-face. From an angle, the mends reflect light, so the position of mends are known – but the repairs remain transparent. Producing a transparent mend has many applications for use in our collections which also include cellulose films, onion skin papers and architectural drawings on tissue.